How To Extend The Life Of Your Air Compressor?

Disclosure: This post may contain affiliate links, meaning if you decide to make a purchase via my links, I may earn a commission at no additional cost to you. See my disclosure for more info.

For most people who bought their air compressors, it is a common scenario to ask how many years will this piece of equipment last? If you intend to use the air compressor for business, you have to understand that it may experience more wear and tear than the air compressor used for random projects at home.

One of the most crucial things that you can always do is to make sure that you have come up with a plan on how to maintain the air compressor. This will give you more years on your equipment.

Table of contents

So what are the best ways to extend the life of your air compressor, the best ways are regular maintenance and inspections of your air compressors systems, so with this in mind lets look at what that entails.

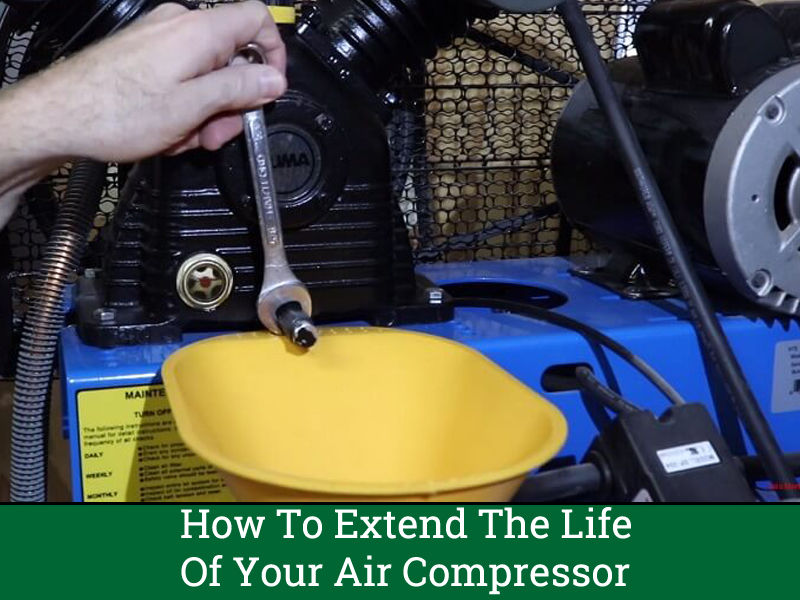

Oil Change

One of the things that most people forget to do regularly is to change the oil in their air compressors. As rule of thumb in the industry, 500-1000 hours should be the basis when to change oil.

Attention should be paid to make sure that the correct type of oil is used when performing and oil change, failure to use the correct oil will result in loss of performance and early failure, which of course is the opposite of what we want.

Regular oil changes with the correct oil guarantees that the air compressor is functioning well.

Clean the Fuel Tank

Another thing you can do is to clean the fuel tank. Once every year, clean the air compressor in order to avoid any trouble of residues building up in your air compressor that could lead to problems in the engine.

Check the Gasket

There is a chance that damage can already be seen on the gasket of your air compressor. This can be a tricky situation for so many instances because instead of releasing the air into the hose, it reverts back to the tank mainly due to the damaged gasket.

Check the Hose for Leaks

Aside from the gasket, another part of the air compressor that should be checked are the hose. Worn and leaky hoses can be the reason why the air compressor is not performing well, so if it is cracked or if it is already corroded, the hose should be replaced.

You should also check all of the hose fittings to make sure that they are sealing correctly and that any hose clamps are tightened correctly and are not leaking.

Keep it Free From Moisture

Rust caused by moisture is a significant factor that can result in severe damage to both the air compressor and its tank. To prevent this, it's crucial to keep the compressor and tank free from any moisture buildup, and promptly drain any visible moisture.

If you have not already extended you drain valve so that it is easier to reach then you might like to check out our article Air Compressor Drain Valve Extension which is a do it yourself project article.

Changing the Filter

One of the simplest things that you can do that can change the overall performance of the air compressor is the regular changing of filters.

Heavy build up of dirt can be fast or slow depending on where you are using the air compressor, or how frequently you use the equipment.

If your air compressor is normally in the one position then ensuring that it is separated from the work environment can be helpful in reducing the air compressors exposure to dirt and dust, which can also increase the life of the air filters.

Shutdown System

Shutdown system is an important factor that you need to ensure as this function ultimately prevents the air compressor to overheat.

Could you imagine if you are using the air compressor to power multiple number of tools and it doesn’t have the right shutdown system?

This could ultimately lead to faster wear and tear, as well as problems occurring in your air compressor from over heating the motor or the electrical system, such instances if not addressed could ultimately lead to bigger problems.

Final Thought

If you are going to purchase an air compressor for business or for your home, you have to ensure that you are looking closely at its overall performance, and its maintenance.

There will come a time when you need to replace some parts, or even the entire unit. During these scenarios, you should never hesitate since it is this maintenance that can keep your air compressor running at its best.

Keep in mind though that maintenance can only be useful up to a point, you need to take into consideration the wear and tear factors so as not to was money. All of this is explained in greater detail in our article Should I Repair or Replace My Air Compressor?

More Resources

We hope you found our article helpful, if you would like to read some more of our articles then we think these below may be interesting for you.