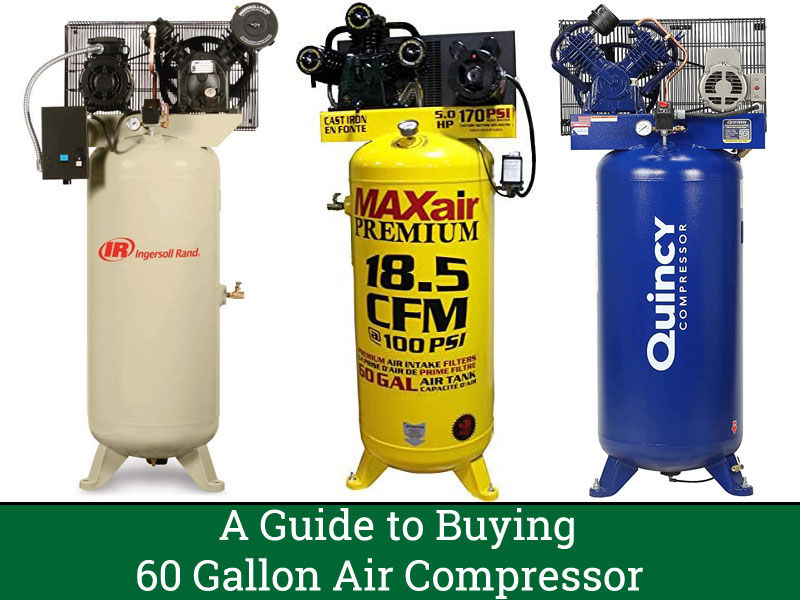

A Guide To Buying A 60 Gallon Air Compressor

Disclosure: This post may contain affiliate links, meaning if you decide to make a purchase via my links, I may earn a commission at no additional cost to you. See my disclosure for more info.

If your considering a new air compressor and you think that a 60 gallon air compressor might be right for your needs but you still have questions, then you have come to the right place. We have written a guide to buying a 60 gallon air compressor precisouly for people like yourself.

We know that there is a lot of information out there, and we also know that a lot of it is confusing, so in our guide to buying a 60 gallon air compressor we will try our best to give you plain speaking information that we think you will find helpful in determining if a 60 gallon air compressor is the right choice for you. Lets get started know.

Table of contents

Who Should Buy 60 Gallon Air Compressor?

If asked about how important using an air compressor is to their daily activities, industrial workers are most likely to be the most vocal on how it has positively influenced their workflow. The use of an air compressor in the industrial settings comes with variation in their day-to-day activities and the sole purpose it serves in this case.

An average industrial work ranges from simple tasks like cleanings to moving heavy goods. In these hard tasks comes into play the role that an air compressor plays in easing manufacturing works that involve heavy-duty processes for perfect execution. Air compressors play a vital roles in such works as material handling and equipment separation. They are often used as an alternative in instances where other forms of energy sources are not allowed for specific operations.

The core purpose of this write up is based solely on informing a potential buyer and admirer of an air compressor (particularly the 60-gallon air compressor) on the choices they hope to make in their stance on going for any model of the air compressor. Said to be the best model of air compressor due to their capabilities to handle heavy industrial works, simple household tasks, the 60-gallon air compressor is built with a feature that makes it stand out. Since all compressors have their distinct qualities, exploiting these feature for choice sake is then necessary.

Purpose of a 60 Gallon Air Compressor?

The first thing that you have to do before buying a 60-gallon air compressor is to decide the purpose for which you are buying it. There are obviously a lot of things that you can do with a 60-gallon air compressor but it is generally used for heavy duty purposes.

A 60-gallon air compressor is ideal for handling equipment like spray guns, sanders, wrenches, and other industrial work tools. The best part about it is that one can use multiple tools at a time with the help of a 60-gallon air compressor.

By managing the pressure point, you can use it in your workspace as well as at home. So, you first have to decide the purpose for which you are buying it and then choose accordingly.

Two-stage vs. Single Stage

If one has to divide an air compressor into categories based on the way the air flows in it, then it could be divided into two basic parts. The first one is a single stage and the second stage is a two stage. The difference between these two types of air compressor depends on the way the air is transferred as energy.

In the single stage compressor, the air that is stuck into the tank is released in a single stroke with a pressure of about 120 psi and then the air passes finally to a storage tank. The final air that is collected in the tank acts as the energy.

In two stages compressor, when the air is released from the first piston, it goes into a second smaller piston where it is compressed again before it finally goes into the storage tank and then it plays the role as energy. The air that is finally collected is doubly pressurized.

Now, the capacity of these two compressors tells you what type of purposes they can serve easily. Therefore, you can choose them accordingly.

Noise Generated - 60 Gallon Air Compressor?

The noise of the air compressor depends on many factors. If we talk about a 60-gallon air compressor, then it is mainly used for heavy duty works. There are chances that most of the compressors that you get in this gallon will create noise. If you are doing some light work with these compressors then they will create comparatively less noise. Along with that, if the air compressor has been used a lot, then there are also chances that it will create noise.

When it comes to noise levels your best approach is to buy a compressor that does not create much noise, check the manufacturer from whom you are buying the compressor so as to establish what noise level the compressor has. After that, you need to take good care of the compressor that you have bought, poor maintenance of your compressor will lead to wear of parts resulting in an increase in noise levels.

As a general guideline though, most 60-gallon air compressors will generate noise levels from between 60 through to 90 decibels (dB) when in operation.

To give you some examples, 70 dB is roughly equivalent to the noise level you would hear from a vacuum cleaner, while 90 dB will be similar to the noise level produced from a motorcycle or a chainsaw. Remember subjecting yourself to prolonged exposure of noise levels above 85 dB can cause people hearing damage, so it is very important that you protect your ears and wear hearing protection at all times when operating a 60-gallon air compressor or any other loud machinery.

Always keep one thing in mind, the less the noise, the more friendly your work environment is and this is all we need while working.

Horsepower - 60 Gallon Air Compressor

We all know that the power or capacity of every machine has its measurement in a certain unit. In the case of the air compressors, it is horsepower. Basically, the capacity of the engine of an air compressor is measured by horsepower.

If someone is buying a consumer ranked air compressor, then its capacity could be around 1.5 to 6.5 HPs. There are definitely compressors with horsepower more than this and even less than this. Those with higher horsepower are generally used for industrial purposes. If we talk about the 60-gallon air compressor, they are good for the use of medium weight works. Thus, the horsepower of these compressors could be in between 1.5 to 6.5.

When you are in the market to buy a 60-gallon air compressor, you should look at the horsepower of the machine and should buy it according to your use. Don't be tempted just to go for the air compressor which has the highest horsepower rating, especially if running cost is a concern. Choose a 60 gallon air compressor which has a horsepower rating sized to your needs, by taking the time to do so you will find that you will save money over the life of the air compressor.

Durability - 60 Gallon Air Compressor

This is something that one should look for each and everything that they buy. It is important to look for the durability of an air compressor for the use of heavy duty works and there should be a surety that they will perform well when in use. For this, one should make sure that they are buying the compressor from a good seller. A good brand never fails to give you the best durable air compressor.

Some common durability factors of an air compressor to take into consideration include:

Build quality: The quality of the materials used in the construction of any air compressor plays a crucial role in determining its durability. High-quality metals, durable plastics, and robust seals and gaskets all ensure that the air compressor can withstand the wear and tear of regular use.

Lubrication system: Excessive wear is a killer of any air compressor so proper lubrication is essential to ensure the moving parts of the air compressor function smoothly. A reliable oil filter and high-quality lubrication system with sufficient oil capacity can extend the life of an air compressor.

Motor protection: The heart of an air compressor is it's motor, and being able to protect it from damage is essential for its longevity. Having an air compressor with features like thermal overload protection, voltage surge protection, and even low oil shutdown can prevent the motor from incurring damage and extend it's life.

Cooling system: Air compressor generate lots of heat during their operation, which inturn can cause damage to its components. Having a high-quality cooling system that includes a reliable fan, heat dissipation fins, and a temperature sensor can all help to prevent overheating and prolong the life of any air compressor.

Maintenance: Conducting proper maintenance is essential for the longevity of an air compressor. Having regular oil changes, filter replacements, and visual inspections of belts and moving parts can catch problems early and thereby prevent them from becoming more significant issues.

By paying attention to all of these durability factors, an air compressor has the best chance of providing reliable and long-lasting performance for years to come.

Frequently Asked Questions

Here are some of the questions that people are asking about air compressors that we think will be helpful for you in making a decision.

Q: How many psi is a 60 gallon air compressor?

A: Industrial Air 60 Gallon air compressor features a large capacity tank providing longer run times for air tools such as ratchets, spray guns and hammers. The air Compressor has a 155 max psi and delivers 11.5 CFM at 90 psi. 3.7 HP, motor with 240-Volt operation.

Q: How many CFM is a 60 gallon air compressor?

A: The Campbell Hausfeld 60-gallon, 3.7 hp, vertical air compressor (VT6195) is ideal for a small shop, automotive enthusiast or serious DIY user. This compressor has high air flow of 10.2 CFM @ 90 PSI to power a wide variety of air tools for grinding, sanding or painting.

Q: Can you lay down a 60 gallon air compressor?

A: If you are transporting a brand new air compressor from the store to your workshop, you will be able to safely transport it on its side, this is only because new air compressor are not usually filled with oil. If on the other hand, you are purchasing a second-hand air compressor, check to see that it has been drained of oil, if not then do not lay it on its side.

Q: What is a good size air compressor for a shop?

A: The correct size of air compressor for a shop depends on the types of tools and equipment that are going to being used. A good rule of thumb is to choose an air compressor that has a capacity of at least 1.5 times the CFM (cubic feet per minute) rating of the highest CFM tool or equipment to be used.

For example, if the highest CFM tool in the shop is rated at 10 CFM, then an air compressor that has a capacity of at least 15 CFM would be recommended. Additionally, the size of the air tank should be large enough so as to provide adequate air storage for the tools being used.

A 60-gallon tank would be a good size as a starting point for use in most small to medium-sized shops.

Final Thoughts

Hopefully we have been able to answer a lot of your questions so that you now feel more confident in knowing if a 60 gallon air compressor is the right choice for you.

In our opinion the ideal buyer for a 60-gallon air compressor would generally be industrial workers or factory environments where a 60-gallon air compressor is ideal for handling equipment like spray guns, sanders, wrenches, and other industrial work tools. These buyers would also be needing to use multiple tools at a time which can be achieved with the help of a 60-gallon air compressor.

The main thing you need to ensure is that you get the air compressor that fits your needs perfectly and hopefully the points we have discussed here will give you much needed requirements that one must consider before buying a 60-gallon air compressor. If you can find all these things in an air compressor, then you should definitely go for it.

More Resources

We hope you found our article helpful, if you would like to read some more of our articles then we think these below may be interesting for you.